Views: 0 Author: Site Editor Publish Time: 2025-09-09 Origin: Site

Pick the right loader size for the roadway. A loader that fits well keeps people safe. It also helps work go faster in small spaces.

Electric loaders are a good choice for underground mining. They make less pollution. They also need less ventilation.

Keep road surfaces smooth to help loaders work better. Smooth roads use less fuel. They also lower repair costs and save time.

Think about both roadway and ventilation when picking a loader. This keeps the mine safe and helps people work well.

Follow local emission rules when picking loaders. This keeps workers and nature safe. It also helps avoid fines.

When picking a loader for underground work, you need to check the roadway size first. The size of the roadway decides which loader can fit and how much power is needed. If the loader is too big, it might not move safely in tight spaces. If the loader is too small, it might not have enough power for heavy loads or steep hills.

Underground mining has many different roadway conditions. Sometimes, the rock changes after mining and makes the roadway unsafe. The ground can shift and push on the walls. This can cause collapses or even rockbursts. Main roadways are used for moving things and for air flow. These roadways often have these problems. Bigger roadways can become unstable more easily, especially if the ground is weak.

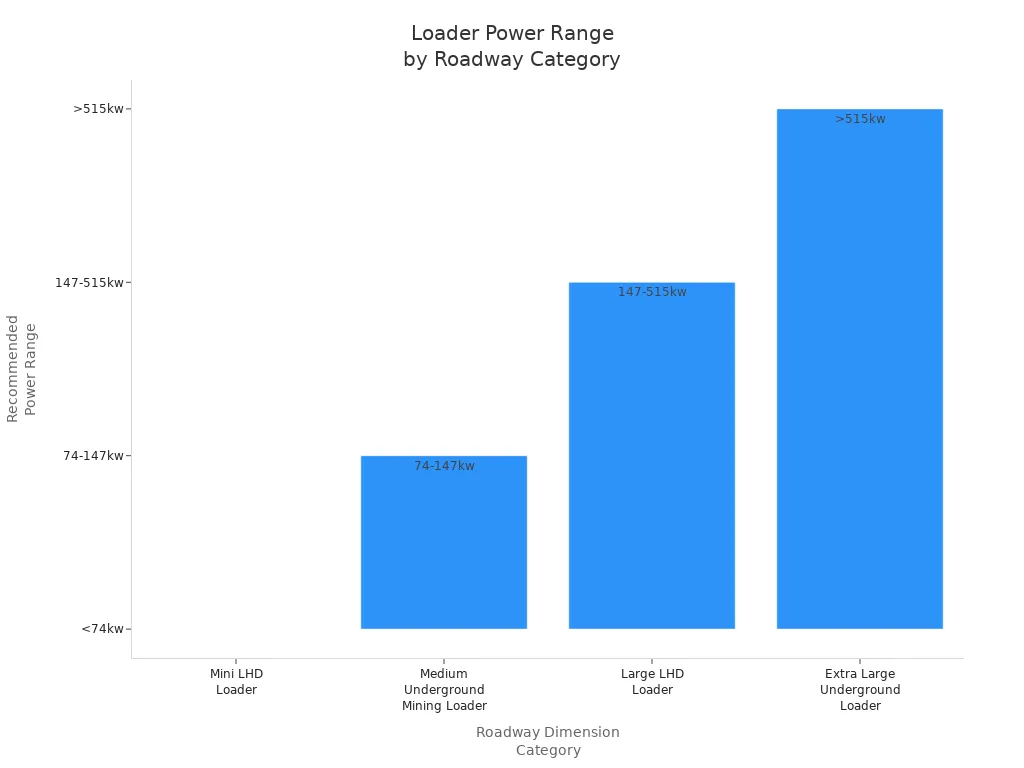

Here is a table to help you match loader power to roadway size:

Roadway Dimension Category | Power Range |

|---|---|

Mini LHD Loader | < 74kw |

Medium Underground Mining Loader | 74~147kw |

Large LHD Loader | 147~515kw |

Extra Large Underground Loader | 515kw< |

If the roadway is narrow or not stable, use a loader with less power and a smaller size. This helps you move safely and lowers the chance of accidents. In bigger and stronger roadways, you can use a loader with more power. This lets you carry more stuff and work faster. Roadway conditions and ventilation needs are connected. If a loader is too strong for a small space, it can make more emissions. This makes it harder to keep the air clean and can hurt safety.

The roadway surface quality affects how well your loader works. If the road is smooth, the loader uses less fuel and needs fewer repairs. If the road is rough or bumpy, the loader works harder. This means it burns more fuel and parts wear out faster.

Smooth roads help save fuel and lower repair needs.

Rough roads make loaders use more energy. This happens because rough surfaces make it harder for loaders to roll.

Many things can change rolling resistance, so it is hard to know exactly how much more fuel you will need.

Spending money on better road care helps your loader last longer. New road machines make it easier to keep roads smooth. This saves money because the loader breaks down less. Making gravel roads better also helps. It makes the road stronger and steadier, so the loader can work longer without trouble. Cleaning roads and fixing holes quickly keeps the surface good. This helps loaders work better and keeps your job running well.

Tip: Good roadway conditions help loaders work better and keep everyone safer underground. Keeping roads in good shape makes it easier for loaders to move and lowers accident risks. It also helps the air system work better because there is less dust and dirt.

When you pick a loader, you must think about ventilation. Ventilation keeps the air clean and removes bad gases. If the air system cannot handle strong loaders, it can be dangerous. Bad gases can fill the mine fast. Workers might get sick or have to leave. If the air is not good, work can slow down or stop.

Note: Good ventilation keeps people healthy and helps the mine run well. Always check the air system before picking a strong loader.

You need to match loader power with the air system. If the loader is too strong, the air cannot clear heat and gases fast enough. This makes the mine unsafe and can stop work until the air gets better.

Here is a table that shows how loader power types affect the mine:

Power Source | Fuel Consumption | Impact on Mine Ventilation | |

|---|---|---|---|

Diesel | High | High | Significant |

Compressed Natural Gas | Moderate | Moderate | Moderate |

Electric | Low | Low | Minimal |

Electric loaders make less pollution and need less air movement. Diesel loaders need more air because they make more fumes and heat. If your mine has weak air flow, electric loaders are safer.

You must follow rules about pollution when picking a loader. These rules keep workers and nature safe. Many places have standards for how much pollution a loader can make. Here are some main standards:

Description | U.S. Equivalent | |

|---|---|---|

Stage IIIB | For underground loaders (300 kW) | Tier 3 |

Stage IV | Lower emissions for underground loaders | Tier 4 |

Stage V | New European standard, no U.S. match | N/A |

If your loader does not meet these rules, you could get fined or shut down. Always check local rules before buying new machines.

Tougher rules make people pick electric loaders instead of diesel ones. Electric loaders help you follow the law and keep the air cleaner. Here is a table that shows how rules change loader choices:

Application Area | Influence on Loader Adoption |

|---|---|

Mining Industry | More electric loaders are used to meet rules. |

Environmental Regulations | Tougher rules make mines use more electric loaders. |

Regulatory Compliance | Laws on diesel push mines to use electric loaders. |

Following the rules makes loaders work better and keeps people safe. Electric loaders make less pollution and need less air. You save money on air systems and keep the mine safe for everyone.

Tip: Always match loader power with air system and pollution rules. This keeps your mine safe, working well, and legal.

You must pick the right loader power for good work. The best loader helps you do more in less time. Loader size matters for moving in tunnels. If the loader fits well, you can load and move things faster. It is easier to drive in small spaces with the right loader. Steep slopes are safer with a loader that can handle them. This makes your work go smoother and faster.

The mine’s environment is important too. Wet or rough places need loaders with strong parts. If you match the loader to the area, it lasts longer. Picking the right loader helps it work better in your mine. Enough power means you can load ore quickly. This lets you move more ore and get more done.

Load-Haul-Dump machines and Low Profile Dump Trucks work together. Good loaders mean fewer trips each shift. This helps you move more ore and do more work. Loader power and how well it works keep the mine running well.

Tip: Always look at your mine’s needs before picking a loader. The right loader keeps workers safe and helps you do more.

Electric loaders help you work better and safer. They do not make tailpipe emissions. This keeps the air cleaner underground. Bad gases like carbon monoxide and nitrogen oxides are lower. This makes the mine healthier for everyone.

Electric loaders make much less heat than diesel ones. You do not need to upgrade air systems as soon. This saves you a lot of money and time. Electric loaders use less power for air systems. You spend less on energy and repairs. The air stays cleaner, so workers stay healthier.

Electric loaders mean you do not need big air systems.

You save money on energy and fixing things.

Picking the right loader helps you work better and safer. Electric loaders make your mine run smoother and save money. This helps everyone in the mine.

You need to think about both the roads and air when picking equipment for underground loading. If you only look at one thing, you might miss something important. This can hurt safety or slow down work. The size and shape of the tunnel decide how big your loader can be. If the tunnel is small or bumpy, you cannot use a big loader. The air system tells you how much heat and fumes the mine can handle. If you use a diesel loader in a small tunnel, you need more air to keep things safe.

You should pick loader power that fits the site. Battery electric vehicles are good for places with bad air flow. These machines help you protect the environment. Electric loaders also help you work faster. They make less heat and do not need as many air system fixes. When you choose equipment, check the tunnel size, the road surface, and the air flow. This helps you pick the best loader for your mine.

Tip: Always think about both the roads and air before you choose. This keeps underground loading safe and helps you work better.

Here are some examples from real mines:

In a small tunnel with weak air flow, you pick an electric loader. This choice helps you work faster and keeps the air clean.

In a big tunnel with strong air flow, you use a large diesel loader. You get more power, but you must watch for fumes and keep the air moving.

When you switch to electric, you see less heat and fewer fumes. Your team works faster, and you spend less money on air systems.

Scenario | Loader Type | Roadway Conditions | Ventilation | Productivity Impact |

|---|---|---|---|---|

Narrow, poor airflow | Electric | Tight, rough | Limited | High |

Wide, strong airflow | Diesel | Spacious, smooth | Ample | High |

Transition to electric | Battery electric vehicles | Mixed | Improving | Increased |

You get better results when you match your equipment to both the roads and air. Smart choices help you keep underground loading safe and make more money.

You always need to pick loader power that fits the road and air rules. If you forget about either one, it can be unsafe and cost a lot. New tools like smart sensors and machines that work by themselves help keep mines safe and follow the rules.

Use computers and data to check if things are safe often.

Pick electric loaders to save money and make things safer.

Get ready for new rules and changes in mining.

Watching for new ideas helps your team stay safe and keeps your mine ready for what comes next.

If you pick a loader that is too strong, you may face safety risks. The loader can make more fumes and heat. Your ventilation system may not keep up. This can slow down work and increase costs.

Electric loaders do not make tailpipe emissions. You get cleaner air underground. You need less ventilation. This saves energy and money. Workers stay safer and healthier.

A smooth roadway helps your loader move easily. You use less fuel and need fewer repairs. Rough surfaces make your loader work harder. You spend more on maintenance and energy.

Yes. You must follow local emission standards. Tougher rules often mean you need electric loaders. These loaders help you meet regulations and keep your mine safe.